SOLIDWORKS Macro - Create Revolve Cut

Objective

In this post, I tell you about how to create Revolve Cut through SOLIDWORKS VBA Macros in a sketch.

This method is most updated method, so use this method if you want to create a new Revolve Cut.

Video of Code on YouTube

Please see below 🎬 video on how to create Revolve Cut from SOLIDWORKS VBA Macros.

Please note that there are no explanation in the video.

Explanation of each line and why we write code this way is given in this post.

Code Sample

Below is the code sample for creating

Revolve Cut.

Option Explicit

' Create variable for Solidworks application

Dim swApp As SldWorks.SldWorks

' Create variable for Solidworks document

Dim swDoc As SldWorks.ModelDoc2

' Creating variable for Solidworks Feature

Dim swFeature As SldWorks.Feature

' Boolean Variable

Dim boolStatus As Boolean

' Revolve Boss/Extrude program

Sub main()

' Setting Solidworks variable to current application

Set swApp = Application.SldWorks

' Check if Solidworks is opened or not

If swApp Is Nothing Then

MsgBox ("Solidworks is not opened")

Exit Sub

End If

' Setting Solidworks document variable to opened part document

Set swDoc = swApp.ActiveDoc

' Check if Solidworks document is opened or not

If swDoc Is Nothing Then

MsgBox ("Solidworks document is not opened. Please open a document.")

Exit Sub

End If

'-----------------------BELOW IS THE SOLUTION----------------------------------------

' Local variables used as Conversion Factors

Dim LengthConversionFactor As Double

Dim AngleConversionFactor As Double

' Use a Select Case, to get the length of active Unit and set the different factors

Select Case swDoc.GetUnits(0) ' GetUnits function gives us, active unit

Case swMETER ' If length is in Meter

LengthConversionFactor = 1

AngleConversionFactor = 1

Case swMM ' If length is in MM

LengthConversionFactor = 1 / 1000

AngleConversionFactor = 1 * 0.01745329

Case swCM ' If length is in CM

LengthConversionFactor = 1 / 100

AngleConversionFactor = 1 * 0.01745329

Case swINCHES ' If length is in INCHES

LengthConversionFactor = 1 * 0.0254

AngleConversionFactor = 1 * 0.01745329

Case swFEET ' If length is in FEET

LengthConversionFactor = 1 * (0.0254 * 12)

AngleConversionFactor = 1 * 0.01745329

Case swFEETINCHES ' If length is in FEET & INCHES

LengthConversionFactor = 1 * 0.0254 ' For length we use sama as Inch

AngleConversionFactor = 1 * 0.01745329

Case swANGSTROM ' If length is in ANGSTROM

LengthConversionFactor = 1 / 10000000000#

AngleConversionFactor = 1 * 0.01745329

Case swNANOMETER ' If length is in NANOMETER

LengthConversionFactor = 1 / 1000000000

AngleConversionFactor = 1 * 0.01745329

Case swMICRON ' If length is in MICRON

LengthConversionFactor = 1 / 1000000

AngleConversionFactor = 1 * 0.01745329

End Select

'----------------------------------------------------------------

' Select Sketch 2 in opened part document

boolStatus = swDoc.Extension.SelectByID2("Sketch2", "SKETCH", 0, 0, 0, True, 0, Nothing, swSelectOption_e.swSelectOptionDefault)

' Check if failed to select sketch 2

If boolStatus = False Then

MsgBox ("Failed to select sketch 2.")

Exit Sub

End If

' Create Revolve Cut Feature

Set swFeature = swDoc.FeatureManager.FeatureRevolve2(True, True, False, True, False, True, swEndConditions_e.swEndCondBlind, swEndConditions_e.swEndCondBlind, AngleConversionFactor * 360, 0, False, False, 0, 0, swThinWallType_e.swThinWallOneDirection, 0, 0, True, False, True)

' Check if Revolve Feature creates or not

If swFeature Is Nothing Then

MsgBox ("Failed to create Revolve Cut Feature.")

Exit Sub

End If

End Sub

Prerequisite

In this article there are some prerequisite.

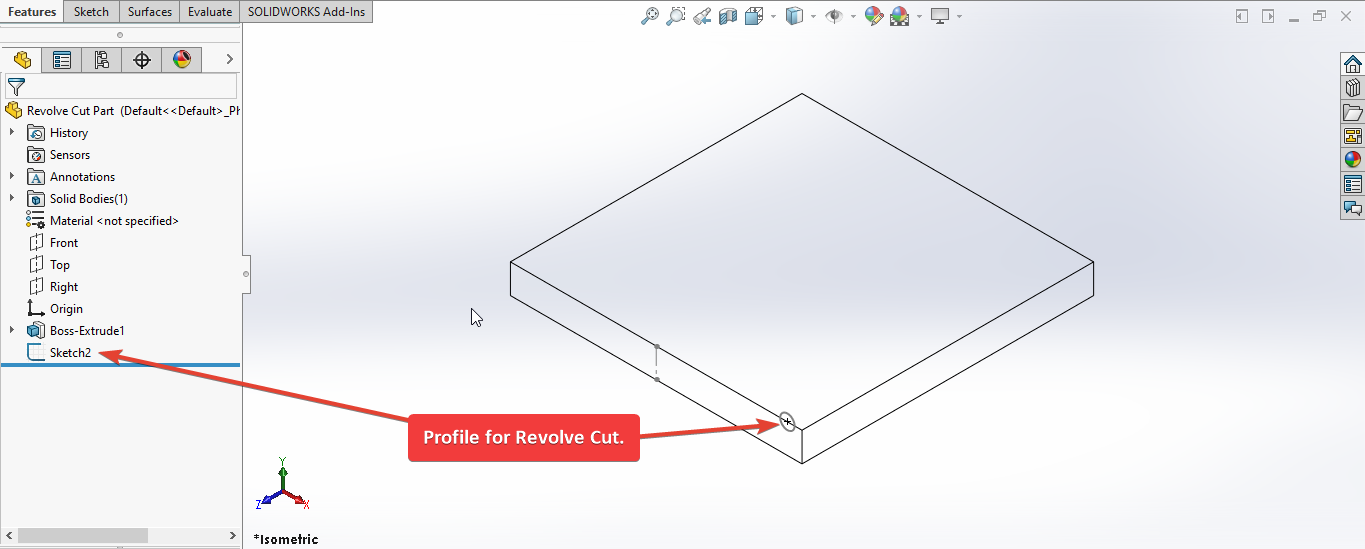

We are not creating sketches from code but we use existing sketch to create Revolve Cut feature as shown in below picture.

As shown in above image, there are 1 sketch and 1 Revolve feature in our part.

Extrude Feature: This is our Extrude part for Revolve Cut feature.Sketch2: This is our profile for Revolve Cut feature.

If you want to create Sketch2

programmatically then please refer to below articles.

- For Circle 👉 read SOLIDWORKS Macros - Create Circle article.

If you want to create Revolve feature programmatically then please refer to below article.

Also, we will apply checks in this article, so the code we write should be error free most of the time.

Understanding the Code

Now let us walk through each line in the above code, and understand the meaning and purpose of every line.

I also give some 📌 links so that you can go through them if there are anything I explained in previous articles.

Option Explicit

This line forces us to define every variable we are going to use.

For more information please visit 👉 SOLIDWORKS Macros - Open new Part document post.

' Create variable for SOLIDWORKS application

Dim swApp As SldWorks.SldWorks

In this line, we create a variable which we named as swApp and the type of this swApp variable is SldWorks.SldWorks.

' Create variable for SOLIDWORKS document

Dim swDoc As SldWorks.ModelDoc2

In this line, we create a variable which we named as swDoc and the type of this swDoc variable is SldWorks.ModelDoc2.

' Creating variable for SOLIDWORKS Feature

Dim swFeature As SldWorks.Feature

In this line, we Create a variable which we named as swFeature and the type of this swFeature variable is SldWorks.Feature.

We create variable swFeature for

SOLIDWORKS Feature.

To see methods and properties related to Feature object, please visit 👉 this

page of SOLIDWORKS API Help

' Boolean Variable

Dim BoolStatus As Boolean

In this line, we create a variable named BoolStatus as Boolean object type.

These all are our global variables.

They are SOLIDWORKS API Objects.

So basically I group all the SOLIDWORKS API Objects in one place.

I have also place boolean type object

at top also, because we use this variable frequently.

Thus, I have started placing it here.

' Main function of our VBA program

Sub main()

End Sub

Next is our Sub procedure which has

name of main.

This procedure hold all the statements (instructions) we give to computer.

' Set SOLIDWORKS variable to SOLIDWORKS application

Set swApp = Application.SldWorks

In this line, we set the value of our SOLIDWORKS variable swApp; which we define earlier; to

SOLIDWORKS application.

' Check if SOLIDWORKS is opened or not

If swApp Is Nothing Then

MsgBox ("SOLIDWORKS is not opened")

Exit Sub

End If

In above line of code, we use an 👉 IF statement to check if SOLIDWORKS application variable is successfully assigned to current SOLIDWORKS application.

' Setting SOLIDWORKS document variable to opened part document

Set swDoc = swApp.ActiveDoc

In above line of code, we set SOLIDWORKS document swDoc variable to currently open part

document.

' Check if SOLIDWORKS document is opened or not

If swDoc Is Nothing Then

MsgBox ("SOLIDWORKS document is not opened. Please open a document.")

Exit Sub

End If

In above line of code, we use an 👉 IF

statement to check if SOLIDWORKS document swDoc is opened.

If SOLIDWORKS document is not opened then code execute inside the code and inform the user by a 👉 Message Window.

After showing message our program exit from here itself.

'-----------------------BELOW IS THE SOLUTION----------------------------------------

' Local variables used as Conversion Factors

Dim LengthConversionFactor As Double

Dim AngleConversionFactor As Double

' Use a Select Case, to get the length of active Unit and set the different factors

Select Case swDoc.GetUnits(0) ' GetUnits function gives us, active unit

Case swMETER ' If length is in Meter

LengthConversionFactor = 1

AngleConversionFactor = 1

Case swMM ' If length is in MM

LengthConversionFactor = 1 / 1000

AngleConversionFactor = 1 * 0.01745329

Case swCM ' If length is in CM

LengthConversionFactor = 1 / 100

AngleConversionFactor = 1 * 0.01745329

Case swINCHES ' If length is in INCHES

LengthConversionFactor = 1 * 0.0254

AngleConversionFactor = 1 * 0.01745329

Case swFEET ' If length is in FEET

LengthConversionFactor = 1 * (0.0254 * 12)

AngleConversionFactor = 1 * 0.01745329

Case swFEETINCHES ' If length is in FEET & INCHES

LengthConversionFactor = 1 * 0.0254 ' For length we use sama as Inch

AngleConversionFactor = 1 * 0.01745329

Case swANGSTROM ' If length is in ANGSTROM

LengthConversionFactor = 1 / 10000000000#

AngleConversionFactor = 1 * 0.01745329

Case swNANOMETER ' If length is in NANOMETER

LengthConversionFactor = 1 / 1000000000

AngleConversionFactor = 1 * 0.01745329

Case swMICRON ' If length is in MICRON

LengthConversionFactor = 1 / 1000000

AngleConversionFactor = 1 * 0.01745329

End Select

'----------------------------------------------------------------

In above line of code, we get and update unit conversion variable as per document unit.

For more detail about why we are using this code sample, please visit 👉 SOLIDWORKS Macro - Fix Unit Issue article.

' Selecting Sketch 2

BoolStatus = swDoc.Extension.SelectByID2("Sketch2", "SKETCH", 0, 0, 0, False, 0, Nothing, swSelectOption_e.swSelectOptionDefault)

In above line, we select the Sketch2 by using SelectByID2 method from Extension object.

For more information about selection method please visit 👉 SOLIDWORKS Macros - Selection Methods post.

' Check if Sketch 2 selected or not

If BoolStatus = False Then

MsgBox ("Fail to select Sketch 2.")

Exit Sub

End If

In above line of code, we use an 👉 IF statement to check if Sketch 2 is selected or not .

If Sketch 2 not selected then we execute code inside the 👉 IF statement and inform the user by a 👉 Message Window.

After showing message our program exit from here itself.

' Create Revolve Cut Feature

Set swFeature = swDoc.FeatureManager.FeatureRevolve2(True, True, False, True, False, True, swEndConditions_e.swEndCondBlind, swEndConditions_e.swEndCondBlind, AngleConversionFactor * 360, 0, False, False, 0, 0, swThinWallType_e.swThinWallOneDirection, 0, 0, True, False, True)

In above line of code we create a Revolve Cut feature.

We create Revolve Cut by setting the value of variable swFeature by FeatureRevolve method.

FeatureRevolve method is part of FeatureManager object.

This FeatureManager is again part of

ModelDoc2 object.

FeatureRevolve2 Method Parameters Details

This FeatureRevolve takes following

parameters as explained:

-

SingleDir -

Trueif the revolve is in one direction,Falseif in both directions. -

IsSolid -

Trueif this is a Solid revolve feature,Falseif not. -

IsCut -

Trueif this is a Cut revolve feature,Falseif not. -

ReverseDir -

Truereverses the angle of the revolution,Falsedoes not; only applies ifDir1Typeis notswEndConditions_e.swEndCondMidPlane. -

BothDirectionUpToSameEntity -

Trueif the revolve is up to the same entity in both directions,Falseif not; only applies ifSingleDirisFalseandDir1TypeandDir2TypeareswEndConditions_e.swEndCondUpToVertex,swEndConditions_e.swEndCondUpToSurface, orswEndConditions_e.swEndCondOffsetFromSurface). -

Dir1Type - Revolve end condition in direction 1 as defined in

swEndConditions_e. as defined below.Member Description swEndCondBlind0 swEndCondMidPlane6 swEndCondOffsetFromSurface5 swEndCondThroughAll1 swEndCondThroughAllBoth9 swEndCondThroughNext2 swEndCondUpToBody7 swEndCondUpToNext11 swEndCondUpToSelection10 swEndCondUpToSurface4 = Do not use; swEndCondUpToVertex3 = Do not use; -

Dir2Type - Revolve end condition in direction 2; as defined in

swEndConditions_eand only applies ifDir1Typeis notswEndConditions_e.swEndCondMidPlaneas defined below.Member Description swEndCondBlind0 swEndCondMidPlane6 swEndCondOffsetFromSurface5 swEndCondThroughAll1 swEndCondThroughAllBoth9 swEndCondThroughNext2 swEndCondUpToBody7 swEndCondUpToNext11 swEndCondUpToSelection10 swEndCondUpToSurface4 = Do not use; swEndCondUpToVertex3 = Do not use; -

Dir1Angle - Angle in radians of revolution in direction 1; only applies if

Dir1TypeisswEndConditions_e.swEndCondBlind. -

Dir2Angle - Angle in radians of revolution in direction 2; only applies if

Dir2TypeisswEndConditions_e.swEndCondBlind. -

OffsetReverse1 -

Trueto reverse the offset direction in direction 1,Falseto not; only applies ifDir1TypeisswEndConditions_e.swEndCondOffsetFromSurface. -

OffsetReverse2 -

Trueto reverse the offset direction in direction 2,Falseto not; only applies ifDir2TypeisswEndConditions_e.swEndCondOffsetFromSurface. -

OffsetDistance1 - Offset distance in direction 1; only applies if

Dir1TypeisswEndConditions_e.swEndCondOffsetFromSurface. -

OffsetDistance2 - Offset distance in direction 2; only applies if

Dir2TypeisswEndConditions_e.swEndCondOffsetFromSurface. -

ThinType - Type and direction as defined in

swThinWallType_e.Member Description swThinWallMidPlan2 swThinWallOneDirection0 swThinWallOppDirection1 swThinWallTwoDirection3 - ThinThickness1 - Wall thickness in direction 1 (if ThinType

is

swThinWallType_e.swThinWallMidPlane, (ThinThickness1)/2 is used for each direction). - ThinThickness2 - Wall thickness in direction 2 (only applies

if ThinType is

swThinWallType_e.swThinWallTwoDirection). - Merge -

Trueto merge the results into a multi-body part,Falseto not. - UseFeatScope -

Trueif the feature only affects selected bodies,Falseif the feature affects all bodies. - UseAutoSelect -

Trueto automatically select all bodies and have the feature affect those bodies,Falseto select the bodies or components that the feature affects.

Return Value : This FeatureRevolve2 method return

feature data object.

To see methods and properties related to Feature object, please visit 👉 this

page of SOLIDWORKS API Help.

In our code, I have used following values:

| Parameter Name | Value Used |

|---|---|

| SingleDir | True |

| IsSolid | True |

| IsThin | False |

| IsCut | True |

| ReverseDir | False |

| BothDirectionUpToSameEntity | True |

| Dir1Type | swEndConditions_e.swEndCondBlind

|

| Dir2Type | swEndConditions_e.swEndCondBlind

|

| Dir1Angle | AngleConversionFactor * 360 |

| Dir2Angle | 0 |

| OffsetReverse1 | False |

| OffsetReverse2 | False |

| OffsetDistance1 | 0 |

| OffsetDistance2 | 0 |

| ThinType | swThinWallType_e.swThinWallOneDirection

|

| ThinThickness1 | 0 |

| ThinThickness2 | 0 |

| Merge | True |

| UseFeatScope | False |

| UseAutoSelect | True |

To see methods and properties related to FeatureManager object, please visit 👉

this

page of SOLIDWORKS API Help.

' Check if Revolve Cut Feature creates or not

If swFeature Is Nothing Then

MsgBox ("Failed to create Revolve Cut Feature.")

Exit Sub

End If

In above line of code, we use an 👉 IF statement to check if we able to create Revolve Cut Feature or not.

If we failed to select then inform the user by a 👉 Message Window.

After showing error message our program exit from here itself.

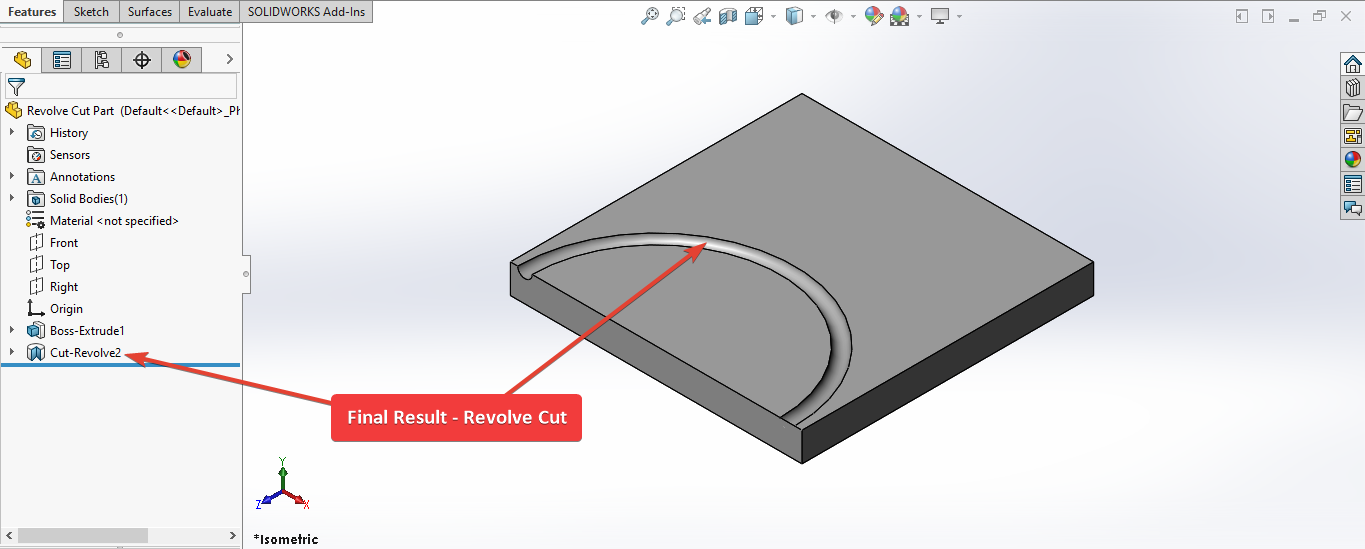

Now we run the macro and after running macro we get Revolve as shown in below image.

This is it !!!

I hope my efforts will helpful to someone!

If you found anything to add or update, please let me know on my e-mail.

Hope this post helps you to create Revolve Cut with SOLIDWORKS VBA Macros.

For more such tutorials on SOLIDWORKS VBA Macro, do come to this blog after sometime.

If you like the post then please share it with your friends also.

Do let me know by you like this post or not!

Till then, Happy learning!!!